Despite the fact that among the list of dearer options We now have reviewed, we ended up blown away by its capabilities and thus we couldn’t leave it from the checklist.

The Mazak Swift Transform one hundred provides the most beneficial of each worlds, a small machine footprint, but with the highest machining high-quality in these days’s machine technology Market.

Peter Jacobs is definitely the Senior Director of selling at CNC Masters, a leading supplier of CNC mills, milling machines, and CNC lathes. He's actively involved with manufacturing processes and frequently contributes his insights for many weblogs in CNC machining, 3D printing, quick tooling, injection molding, metal casting, and manufacturing generally. You are able to hook up with him on his LinkedIn.

It’s much from low-cost, though the Genos L25011 is an excellent machine for industrial CNC lathing. This machine is made by Okuma, which has become the biggest names inside the CNC lathe field, to help you be sure it’s of excellent good quality.

EDM machines use present-day discharges and an electric area to remove chips through the workpiece. Two electrodes are applied, with electrical fields intensified by going the electrodes nearer to each other in order to cut pieces. A dielectric liquid separates The 2 electrodes and facilitates the voltage.

M codes are Portion of the programming language for CNC machines, controlling the miscellaneous functions that do not require the movement of your tool. Examples consist of M03 for spindle get started and M05 for spindle end.

Supply: YouTube A different amazing attribute would be the thermo-helpful building. It includes a thermo Lively stabilizer which routinely compensates thermal results to take care of limited tolerances.

Regardless if you are looking for a modest CNC lathe with live tooling, or a typical 2-axis machine, MAZAK will likely have you included.

Another way is to only use CAD-CAM software which allows the look engineer check the producibility with the element. The highly effective simulation tools can visualise The entire course of action from raw material to the final merchandise, even utilizing the input with regards to finishing needs.

The method is controlled by Computer system software, which ensures precision and regularity in every section made.

This is certainly also a consumer-pleasant lathe, thanks to the individual cooling tank for fast servicing, uncomplicated spindle entry to reduce operator perform stress, and diminished chip accumulation. Furthermore, it has a friendly user interface with a library of apps for easy setup and Procedure.

Ad cookies are used to provide people with appropriate advertisements and promoting strategies. These cookies observe website visitors across Internet sites and accumulate info Read more to offer personalized advertisements. Other people Some others

Axial Lower depth. Pretty self-explanatory because it shows the depth of a Slash inside the axial way. It's the key parameter for facing operations. A higher feed fee puts additional pressure within the slicing tool, shortening its life time.

5. Floor Complete: The desired surface area end can impact machining. Rough finishes are more quickly and more affordable, though high-high quality finishes could require further methods and prices. You are able to learn more about many of the most preferred surface finishing options.

Devin Ratray Then & Now!

Devin Ratray Then & Now! Bug Hall Then & Now!

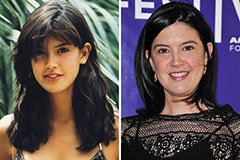

Bug Hall Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!